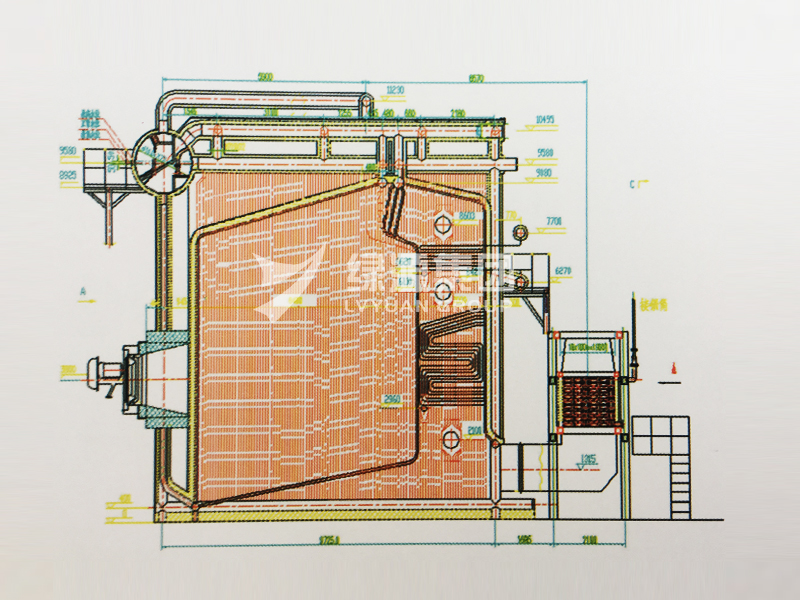

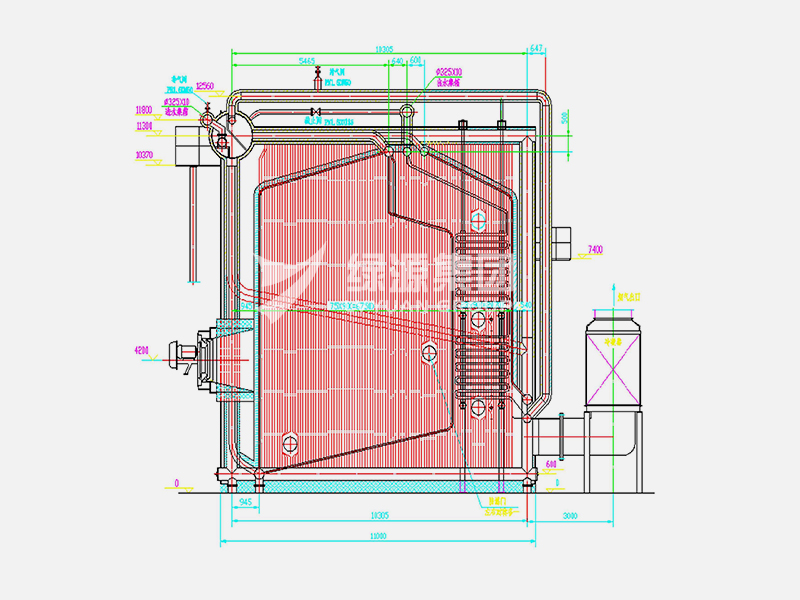

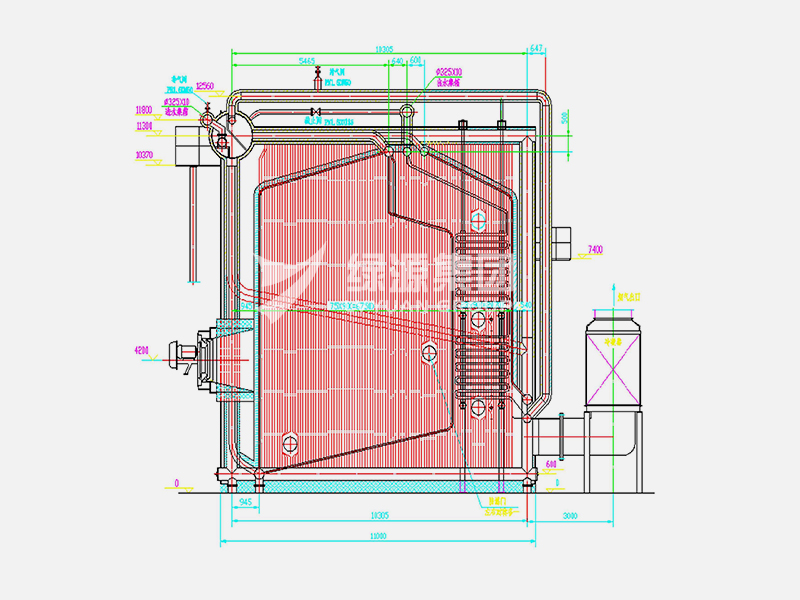

Yingkou luyuan boiler is A class A boiler manufacturer. The hot water type oil (gas) boiler is introduced for GEF project and adopts the Angle tube type full membrane type water wall structure.The furnace chamber is completely closed with membrane water cooling wall, the convection heating surface is made of serpentine tube structure, and the boiler flue gas outlet is equipped with external condenser.The furnace type of the structure is suitable for 29~116MW.

The steam type fuel oil (gas) boiler adopts the Angle tube structure, the furnace chamber is the membrane type water cooling wall completely closed structure, the convection channel upper part is the serpentine tube superheater, the lower part is the flag heating surface, the boiler flue gas outlet external condenser.

Product features

Good safety

1.As the boiler adopts the full membrane water wall structure and the furnace chamber part adopts the completely closed structure, it can ensure the continuous micro-positive pressure combustion and reduce the heat loss.Boiler overall output full, high thermal efficiency.

2.Large furnace space, flexible burner layout, full combustion.

3.The boiler flue gas outlet is equipped with condenser, which can ensure the overall thermal efficiency of the boiler ≥93%.

Convenient maintenance

The design of the burner and the furnace adopts the symmetrical arrangement in the center, so as to ensure the heating of each heating surface is basically uniform and ensure the safety of water circulation.The boiler below 46MW adopts the single burner furnace front wall central arrangement, the boiler above 58MW adopts the double burner furnace front wall parallel arrangement.

Good economic benefit

Modular design, easy to manufacture, fast installation, short construction period.

Due to the use of full membrane wall, furnace wall with light structure, light weight, low infrastructure costs.

Sweep WeChat yards pay attention to us

Sweep WeChat yards pay attention to us